La mejor opción para almacenamiento en frío. La conductividad térmica del PU es de 0,021 W/(m · K), lo que le confiere un excelente aislamiento térmico. Utilizamos placas de alta resistencia, un diseño de empalme único, una instalación más cómoda y una mayor resistencia al impacto. Es ignífugo y resistente a la humedad, con diversas especificaciones y flexibilidad de personalización.

Número de artículo :

PUWall0001Pedido (MOQ) :

500 mPago :

USD 30% PPColor :

CustomizedDensidad del material del núcleo :

40 Kg/m³Puerto de embarque :

Qingdao, ChinaPlazo de entrega :

30-45 daysOrigen del producto :

Shandong, China

Presupuesto | |

Tipo | |

Densidad | 40~45 kg/m³ |

Espesor | 40/50/60/75/80/100/120/150/200 mm |

Espesor de la piel del metal | 0,4~0,8 mm |

Ancho efectivo del panel | 1000 mm para pared y techo |

Material de la piel | PPGL, PPGI, acero inoxidable, bobina de aluminio |

Prepintado | PE/SMP/HDP/PVDF, etc. |

Grado ignífugo | B1 |

Conductividad térmica | ≤0.023/≤0.02 |

Rango de temperatura | 40~43/40~50℃ |

Longitud | Máximo 11,9 m o personalizado. |

Se aceptan diseños personalizados. | |

Fuerte rendimiento de aislamiento La conductividad térmica del poliuretano es extremadamente baja (≤ 0,024 W/(m · K)), lo que lo convierte en uno de los mejores materiales de aislamiento térmico actuales y minimiza el intercambio de calor dentro y fuera de la biblioteca. Incluso en cámaras frigoríficas a temperaturas ultrabaja (por debajo de -30 °C), mantiene una temperatura baja estable, reduce significativamente el consumo energético de los equipos de refrigeración y disminuye los costes operativos a largo plazo. Estructura compacta, buen sellado. Al espumar poliuretano, se adhiere firmemente a la placa metálica sin dejar huecos. La unión está diseñada con una ranura machihembrada o una ranura de sellado, y el sellador previene eficazmente las fugas de aire frío y la humedad externa, reduce la formación de escarcha en el almacén y garantiza la eficiencia de la refrigeración. Alta resistencia, fuerte durabilidad. El material del núcleo de poliuretano en sí tiene una buena resistencia a la compresión (densidad ≥ 40 kg/m, resistencia a la compresión ≥ 0,3 MPa), con acero de color, acero inoxidable y otras capas superficiales, excelente resistencia al impacto y resistencia a la deformación, puede soportar la presión del apilamiento de mercancías y la instalación de equipos, y tiene una vida útil de 15 a 20 años. Resistencia a bajas temperaturas y antienvejecimiento. En el rango de -40 ℃ a temperatura normal, las propiedades físicas son estables, sin riesgo de fragilización y agrietamiento; el material del núcleo tiene una fuerte estabilidad química, no es fácil de degradar debido a cambios de baja temperatura o humedad y es adecuado para entornos de baja temperatura a largo plazo. Construcción flexible Se puede prefabricar de acuerdo con el tamaño del almacenamiento en frío (espesor 50-200 mm opcional), peso ligero, empalme conveniente, puede acortar el ciclo de instalación; Y admite personalización de formas especiales, se adapta a diferentes estructuras de almacenamiento en frío (como particiones de alta y baja temperatura, esquinas).

3 Especificaciones técnicas del panel sándwich de PU PIR para cámara frigorífica

| Espesor/mm | Diferencia de temperatura entre el interior y el exterior/℃ | Altura del panel de pared/m | Longitud del panel del techo/m | Temperatura de almacenamiento en frío aplicable/℃ |

| 100 | 30 | 5 | 4.45 | -15 |

| 125 | 35 | 5.5 | 5.2 | -20 |

| 150 | 50 | 6 | 5.85 | -25 |

| 175 | 65 | 6.5 | 6.3 | -30 |

| 200 | 75 | 7 | 6.8 | -40 |

Los datos de la tabla izquierda solo corresponden al panel sujeto a la diferencia de presión interna-externa y a la presión de contracción, sin carga de viento. Si se excede la longitud/altura especificada o se produce carga de viento, se requieren soportes para el panel.

Los datos anteriores se calculan de acuerdo con el flujo de calor de 8~10 W/m2.

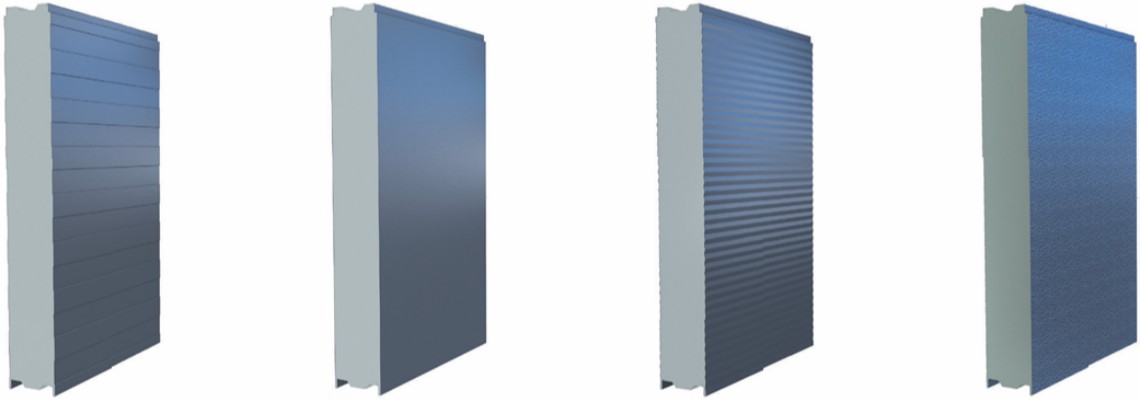

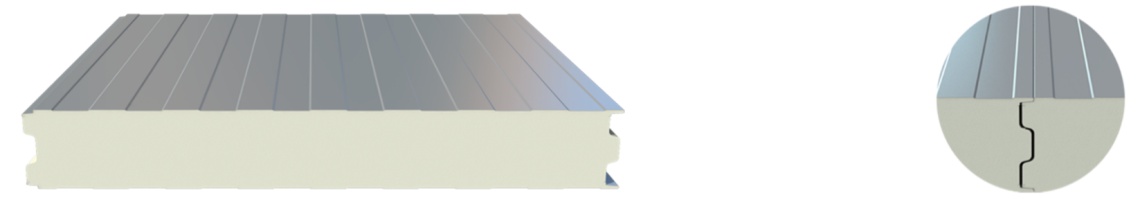

4 Tipo de placa y figura de nodo

Interfaz enchufable para placa de almacenamiento en frío, tipo C

Interfaz enchufable para placa de almacenamiento en frío, tipo E

5 áreas de aplicación de los paneles de almacenamiento frigorífico

·Procesamiento rápido de congelados y refrigeración de alimentos.

·Planta de procesamiento de alimentos

·Almacenamiento de productos lácteos

·Productos biológicos y medicamentos

·Almacenamiento frigorífico interior

·Almacenes frigoríficos para vehículos de transporte en cadena de frío

6 Certificación de paneles sándwich de PU/PIR para cámaras frigoríficas

Propanel Panel sándwich para cámara frigorífica Ha obtenido con éxito certificaciones internacionales de prestigio como CE, FM y UL gracias a su excelente calidad. Con la certificación CE, cumple con las normas de seguridad, salud y protección ambiental de la Unión Europea y puede comercializarse libremente en el mercado europeo. La certificación FM indica un rendimiento excepcional en resistencia al fuego y al viento, y puede afrontar eficazmente los desafíos de diversos entornos industriales y comerciales. La certificación UL confirma además que el producto cumple con las normas de seguridad eléctrica, resistencia al fuego y estabilidad del material, cumpliendo con los estrictos requisitos. Estas certificaciones son un testimonio de la solidez y destacan la fiabilidad y la alta calidad de los paneles sándwich de lana de roca a nivel mundial. Ya sea en el ámbito del aislamiento de edificios o la seguridad contra incendios, ofrece a los clientes una protección fiable.

Derechos de autor

@ 2026 CHENGDU PROPANEL TECH CO., LTD. Reservados todos los derechos

.  RED SOPORTADA

RED SOPORTADA

Hi! Click one of our members below to chat on