La mejor opción para materiales de construcción que ahorran energía. Excelentes propiedades de aislamiento térmico y térmico, con una conductividad térmica de 0,024-0,041 W/m·K, lo que reduce el consumo de energía. Ligero pero con gran resistencia, fácil de instalar. Económico, de alta durabilidad y con propiedades impermeables e ignífugas. Se puede personalizar según las necesidades de la construcción.

Número de artículo :

EPSWALL0001Pedido (MOQ) :

500 mPago :

USD 30% PPColor :

CustomizedDensidad del material del núcleo :

18 Kg/m³Puerto de embarque :

Qingdao, ChinaPlazo de entrega :

30-45 daysOrigen del producto :

Shandong, China

Presupuesto | |

Tipo | Panel de pared sándwich de poliestireno expandible |

Espesor | 50/75/100/120/150/200 mm |

Espesor de la piel del metal | 0,4~0,8 mm |

Ancho efectivo del panel | 950/980 mm |

Densidad | 8/10/12/14/16/18/20 kg/m³ |

Material de la piel | PPGL, PPGI, acero inoxidable, bobina de aluminio |

Prepintado | PE/SMP/HDP/PVDF, etc. |

Grado ignífugo | B2 |

Conductividad térmica | 0.042 |

Rango de temperatura | -40~90℃ |

Longitud | Máximo 11,9 m o personalizado. |

Se aceptan diseños personalizados. | |

Excelentes propiedades de aislamiento térmico y conservación del calor, reduciendo los costes de consumo energético.

La conductividad térmica del núcleo de EPS es extremadamente baja (normalmente ≤ 0,041 W/(m·K)), muy superior a la de las paredes de ladrillo tradicionales (con una conductividad térmica de aproximadamente 0,81 W/(m·K)). Bloquea eficazmente la transferencia de calor entre el interior y el exterior, logrando así el ahorro energético y la protección del medio ambiente, y en consonancia con el concepto de edificios ecológicos y energéticamente eficientes.

Ligero y de alta resistencia, reduciendo la carga estructural.

La densidad del núcleo de EPS es de tan solo 8-28 kg/m³. Al combinarse con paneles metálicos, el peso total del panel es mucho menor que el de las paredes de ladrillo del mismo espesor (una pared de ladrillo pesa aproximadamente 190 kg/m³). Este material ligero no solo reduce el coste de construcción de la cimentación, sino que también evita los riesgos de seguridad causados por un peso estructural excesivo. Asimismo, la capa exterior de la placa de acero de color posee una gran resistencia a impactos y deformaciones, capaz de soportar pequeñas colisiones durante el uso diario, garantizando así la estabilidad a largo plazo de la pared.

Excelente efecto de aislamiento acústico, mejorando el confort del espacio.

La estructura interna del núcleo de EPS es una estructura de panal cerrada, que absorbe eficazmente las ondas sonoras y reduce la transmisión de ruido. El aislamiento acústico del EPS convencional... paneles de pared Puede superar los 40 dB. Si se utiliza un núcleo de doble capa o una capa superficial especial, el aislamiento acústico puede superar los 45 dB.

La resistencia al fuego cumple con los estándares, lo que garantiza la seguridad de uso.

Al añadir retardantes de llama, los paneles de pared de EPS pueden alcanzar el nivel B1. Además, el material del núcleo de EPS no produce gases tóxicos al calentarse y genera menos humo al quemarse, lo que permite mayor tiempo para la evacuación del personal y mejora aún más el coeficiente de seguridad del edificio.

Construcción conveniente y eficiente, acortando el período de construcción.

Los paneles de pared de EPS son, en su mayoría, componentes estandarizados prefabricados en fábrica, y los bordes laterales están diseñados con estructuras de conexión machihembradas o de mortaja y espiga. La construcción en obra solo requiere empalmes y fijación con pernos y piezas de conexión, lo que reduce el tiempo de construcción en más de un 60 %. Además, el panel es ligero y no requiere grandes equipos de elevación. El transporte y la instalación son manuales, lo que reduce eficazmente los costos de construcción y el tiempo empleado.

Fuerte resistencia a la intemperie, lo que reduce el mantenimiento posterior.

El material del núcleo de EPS presenta una buena estabilidad química y no se erosiona fácilmente por factores ambientales como la humedad, las altas temperaturas y el ácido-base. Es poco probable que presente problemas como moho, corrosión o grietas tras un uso prolongado. La capa exterior de la placa de acero de color suele estar galvanizada o pintada en aerosol, lo que le confiere una excelente capacidad anticorrosiva y una vida útil de 15 a 20 años en exteriores. Tras la instalación del panel de pared de EPS, el coste de mantenimiento es solo entre un tercio y la mitad del de las paredes de ladrillo tradicionales, lo que permite a los usuarios ahorrar una cantidad significativa de mano de obra e inversión financiera.

Carga vertical admisible y coeficiente de transferencia de calor de PROPANEL Panel de techo sándwich de EPS (deflexión admisible f ≤ L/240)

Espesor (mm) | Transferencia de calor (W/㎡·k) | Peso | Carga P=KN/m2 | 0.6 | 0.8 | 1 | 1.2 | 1.5 |

50 | 0.64 | 10 | L(m) | 6.5 | 5.8 | 5.1 | 4.6 | 4 |

75 | 0.43 | 10.45 | L(m) | 7.8 | 7 | 6.2 | 5.6 | 5 |

100 | 0.32 | 10.9 | L(m) | 9.5 | 8.5 | 7.5 | 6.8 | 6 |

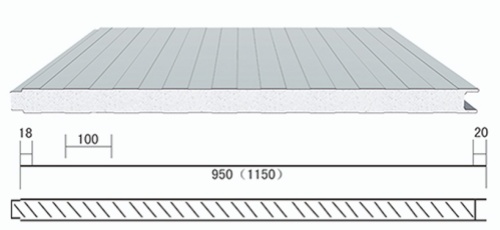

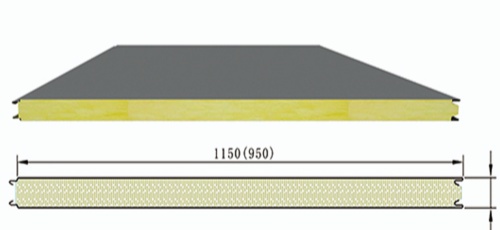

3 tipos de juntas para paneles de pared sándwich de EPS

Hay 2 tipos de traslape para el panel sándwich de pared de EPS: uno es el tipo de tapa y otro es el tipo de superposición.

Las imágenes son las siguientes:

Panel de pared tipo enchufe 950 1150

Panel de pared tipo S-Socket 950 1150

4 Aplicaciones del panel sándwich de pared de EPS

Los paneles de pared de EPS se utilizan ampliamente en la industria de la construcción debido a sus propiedades livianas, aislantes, insonorizantes y resistentes al fuego.

En edificios industriales, son la opción preferida para las paredes de plantas industriales. Su ligereza reduce la carga sobre la estructura principal y los costos. Su buen aislamiento reduce el consumo de aire acondicionado y calefacción, lo que los hace ideales para talleres con requisitos de temperatura. Además, son fáciles de instalar, lo que acorta el plazo de construcción y satisface las necesidades de las empresas de producción rápida.

En edificaciones civiles, se utilizan principalmente en viviendas de baja altura, casas rurales autoconstruidas y casas prefabricadas. Los muros exteriores ofrecen un excelente aislamiento acústico, lo que mejora el confort de la vivienda; los muros interiores reducen su espesor y aumentan la superficie útil. Al incorporar retardantes de llama, alcanzan el nivel de resistencia al fuego B1, cumplen con las normas de seguridad contra incendios, ofrecen una excelente resistencia a la intemperie y reducen los costos de mantenimiento.

En edificios públicos, se encuentran comúnmente en oficinas de ventas temporales, aulas temporales en escuelas y salas de aislamiento en hospitales. El método de prefabricación en fábrica y montaje in situ permite completar un edificio de 100 m² en 3-5 días. Tras el desmontaje, algunos paneles pueden reutilizarse, lo que se ajusta al concepto de construcción sostenible. Su aislamiento permite mantener una temperatura interior adecuada.

Además, se utilizan en el almacenamiento en cadena de frío para reducir la pérdida de calor y disminuir el consumo de energía; en invernaderos agrícolas, ayudan a mantener temperaturas estables y son resistentes a la corrosión, capaces de soportar la erosión ambiental por alta humedad.

5 Casos de proyectos de Panel Sándwich de Pared EPS

Casos de proyectos de paneles sándwich de EPS - almacén logístico brasileño

Casos de proyectos de paneles sándwich de EPS para techos - Fábrica japonesa de equipos electrónicos

Derechos de autor

@ 2026 CHENGDU PROPANEL TECH CO., LTD. Reservados todos los derechos

.  RED SOPORTADA

RED SOPORTADA

Hi! Click one of our members below to chat on