El panel sándwich de lana de roca ignífugo para muros PROPANEL es una excelente opción para el cerramiento de naves industriales. Se seleccionan dos capas de placas de acero recubiertas de color de alta calidad u otras placas metálicas como placa base. La lana de roca se adhiere firmemente a las placas metálicas mediante un adhesivo de alta adherencia. El panel de lana de roca para muros presenta una incombustibilidad de nivel A, excelentes propiedades de aislamiento térmico, un excelente aislamiento acústico, es robusto, duradero, ecológico y atractivo.

Número de artículo :

ROCKWALL0001Pedido (MOQ) :

500 mPago :

USD 30% PPColor :

CustomizedDensidad del material del núcleo :

120 Kg/m³Puerto de embarque :

Qingdao, ChinaPlazo de entrega :

30-45 daysOrigen del producto :

Shandong, China

Presupuesto | |

Tipo | Panel sándwich de lana de roca de metal recubierto de color |

Densidad | 50~200 kg/m³ |

Espesor | 50/75/100/120/150 mm |

Espesor de la piel del metal | 0,4~0,8 mm |

Ancho efectivo del panel | 1000 mm para pared y 950/1000 mm para techo |

Material de la piel | PPGL, PPGI, acero inoxidable, bobina de aluminio |

Prepintado | PE/SMP/HDP/PVDF, etc. |

Grado ignífugo | A |

Conductividad térmica | 0,04~0,055 |

Rango de temperatura | 800℃ |

Longitud | Máximo 11,9 m o personalizado. |

Se aceptan diseños personalizados. | |

Excelente resistencia al fuego. lana de roca Es un material inorgánico con una clasificación de resistencia al fuego de nivel A (no combustible), muy superior a la de la mayoría de los materiales con núcleo orgánico. Es adecuado para entornos con estrictos requisitos de seguridad contra incendios, como hospitales, escuelas y edificios de gran altura, previniendo eficazmente la propagación del fuego y mejorando el coeficiente de seguridad del edificio.

Combina aislamiento acústico y conservación del calor. Las fibras de lana de roca tienen una estructura porosa con un aislamiento acústico superior a 40 dB, lo que permite bloquear el ruido externo. Su conductividad térmica es de aproximadamente 0,044 W/(m·K) y su efecto aislante es similar al del EPS. Reduce el consumo de energía para calefacción en invierno y bloquea las altas temperaturas en verano, satisfaciendo así las necesidades de confort en entornos residenciales e industriales.

Fuerte resistencia al envejecimiento y a la intemperie. La lana de roca posee una alta estabilidad química, es resistente a ácidos y álcalis, y a la humedad. Es poco probable que se enmohezca o deforme con el uso prolongado. La placa exterior de acero coloreada cuenta con un tratamiento anticorrosivo y su vida útil en exteriores puede superar los 15 años. La capa superficial de mortero de cemento es resistente a los rayos ultravioleta y a la erosión pluvial. No requiere mantenimiento frecuente, lo que reduce los costos de mantenimiento.

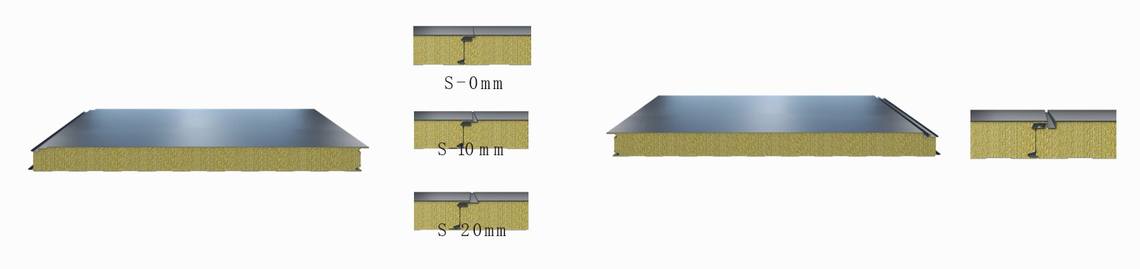

Construcción conveniente y amplia adaptabilidad. La mayoría son componentes estandarizados prefabricados en fábrica. El lateral está equipado con una estructura de empalme. No se requieren procedimientos complejos en obra. Un equipo de 2 a 3 personas puede completar la instalación rápidamente. Su peso es moderado, no se requieren grandes equipos de elevación y es adecuado para diversos edificios, como fábricas, almacenes y viviendas. Es especialmente adecuado para escenarios con requisitos duales de resistencia al fuego y aislamiento acústico.

Carga vertical admisible y coeficiente de transferencia de calor de PROPANEL Panel sándwich de pared de lana de roca ignífugo de nuevo modelo con sellado de poliuretano (deflexión admisible f ≤ L/240)

Espesor (mm) | Transferencia de calor (W/m2k) | Peso (kg) | Carga P=KN/m2 | 0.60 | 0.80 | 1.00 | 1.20 | 1,50 |

50 | 0,75 | 15.74 | L(m) | 3.78 | 3.31 | 2.98 | 2.71 | 2.41 |

75 | 0,53 | 18.68 | L(m) | 4.83 | 4.21 | 3.76 | 3.42 | 3.01 |

100 | 0.41 | 21.62 | L(m) | 5.77 | 5.02 | 4.47 | 4.04 | 3.55 |

150 | 0.31 | 27.51 | L(m) | 7.53 | 6.54 | 5.82 | 5.26 | 4.61 |

Nota: chapa de acero exterior de 0,5 mm y chapa de acero interior de 0,4 mm.

El sándwich de lana de roca Panel de pared Se elabora mediante un proceso de producción preciso, ofreciendo características excepcionales como resistencia al fuego, aislamiento térmico y durabilidad. A partir de bobinas de acero inoxidable y bobinas galvanizadas con recubrimiento de color como sustratos superior e inferior, los paneles adquieren resistencia a la corrosión y un acabado elegante. Estas bobinas se desenrollan eficientemente y, posteriormente, se aplica una película para proteger las láminas de acero de rayones. Posteriormente, las láminas se corrugan para mayor resistencia y capacidad de carga, lo que las hace ideales para uso estructural.

A continuación, las láminas de acero se precalientan para garantizar una fuerte adhesión, mientras que las tiras de lana de roca (el material del núcleo) se preparan por sus excelentes propiedades ignífugas, aislantes y acústicas. La lana de roca se une en cruz para formar un núcleo sin costuras, maximizando así la eficiencia térmica. Una sección de pulverización mejora la durabilidad de la superficie, seguida de un sellado lateral opcional de poliuretano para mayor hermeticidad y resistencia a la humedad, o bien, sin sellado, según las necesidades del proyecto.

Los paneles se someten a un curado con doble oruga, lo que garantiza una unión robusta entre las capas con calor y presión uniformes. Posteriormente, se cortan en piezas con precisión para obtener el tamaño perfecto, se apilan cuidadosamente para evitar daños y se embalan automáticamente para un envío seguro. Este proceso crea un panel de alto rendimiento apto para aplicaciones industriales, comerciales y residenciales, que ofrece eficiencia energética, seguridad y durabilidad en una sola solución.

4 Casos de proyectos de Panel de Muro Sándwich de Lana de Roca

Casos de proyectos de Panel Sándwich de Muro de Lana de Roca--Proyecto BD de 6000 metros cuadrados en Estados Unidos en 2018

Casos de proyectos de Panel Sándwich de Muro de Lana de Roca--Fábrica de electrónica de Indonesia en 2005, 9000 metros cuadrados

5 Honores y certificación de Propanel

El panel sándwich de lana de roca de Propanel ha obtenido con éxito certificaciones internacionales de prestigio como CE, FM y UL gracias a su excelente calidad. Con la certificación CE, cumple con las normas de seguridad, salud y protección ambiental de la Unión Europea y puede comercializarse libremente en el mercado europeo. La certificación FM indica un rendimiento excepcional en resistencia al fuego y al viento, y puede afrontar eficazmente los desafíos de diversos entornos industriales y comerciales. La certificación UL confirma además que el producto cumple con las normas de seguridad eléctrica, resistencia al fuego y estabilidad del material, cumpliendo con los estrictos requisitos. Estas certificaciones demuestran la solidez y la alta calidad de los paneles sándwich de lana de roca a nivel mundial. Tanto en el ámbito del aislamiento de edificios como en el de la seguridad contra incendios, ofrece a los clientes una protección fiable.

Derechos de autor

@ 2026 CHENGDU PROPANEL TECH CO., LTD. Reservados todos los derechos

.  RED SOPORTADA

RED SOPORTADA

Hi! Click one of our members below to chat on